Combined Slitting and Cross-Cutting

The flattening and cross-cutting lineoffers two options for coil leveling: the Spotti leveling unit for coils of 1.0 – 5.0×1500 mm, and the Fimi leveling unit for coils of 0.4 – 3.0×1500 mm. The raw materials used include hot rolled pickled, cold rolled, and galvanized steel strips. The processed products are leveled sheets cut to length or through blanking, as well as wide strips cut to size. Processing range includes thicknesses from 0.35 to 5 mm, sheet lengths from 350 to 12000 mm, and a maximum width of 1500 mm. The minimum format for sheets or blanks is 350×350 mm. Maximum sheet pack height is 150 mm, and the coil weight can reach up to 40 tons.

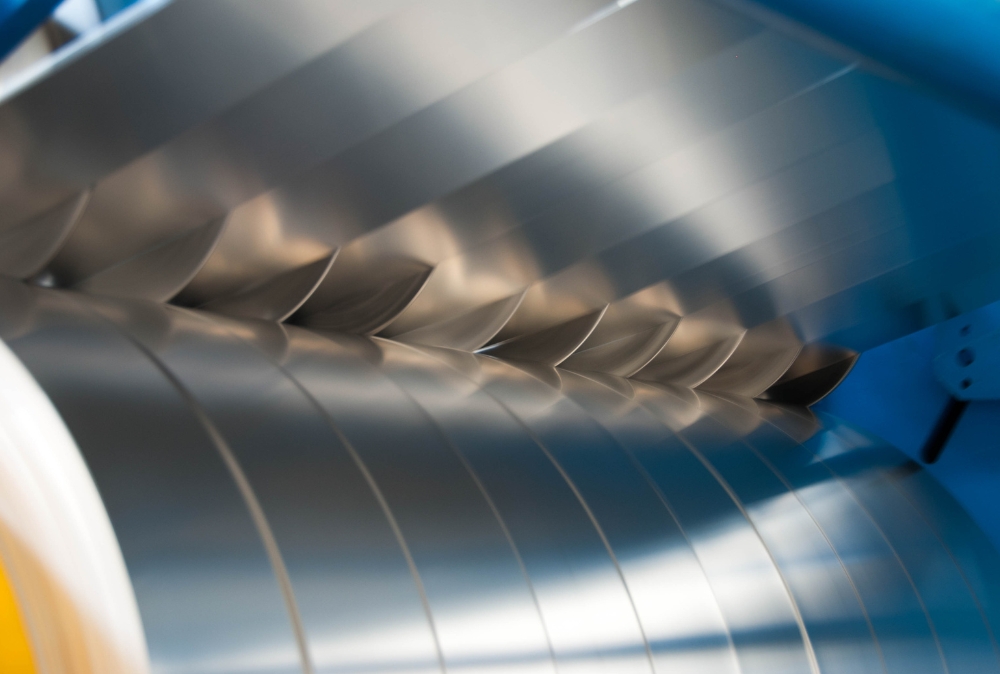

The slitting and/or recoiling line handles hot rolled pickled, cold rolled, galvanized, pre-painted, or stainless steel strips. The resulting products include slit coils (rings) and/or recoiled strips. Processing specifications include thicknesses from 0.25 to 3.0 mm and widths from 24 to 1500 mm, with up to 25 strips per coil. Strip width tolerance is ±0 mm. The internal coil diameter is 500 mm, external diameter up to 2200 mm. Packaging can be done with horizontal or vertical axis. Maximum coil weight is 22 tons.

The combined slitting/recoiling and/or cross-cutting processes cold rolled, galvanized, or pre-painted strips. The final products are slit coils (rings), sheets cut to length, or blanks. The processing range includes thicknesses from 0.35 to 2.5 mm, widths from 75 to 1500 mm, and sheet lengths from 350 to 8000 mm. The minimum blank format is 75×350 mm. Maximum height of the sheet pack is 500 mm, with a weight up to 6 tons. Coil inner diameter is 500 mm, outer diameter up to 1200 mm, and maximum strip weight is 7 tons.